覆盖(Cover)层:拉伸强度(strength)不小于15mpa,扯断伸长度不小于350%,磨耗量≤200mm3,层间粘合强度(strength)纵向试样平均值(Theaveragevalue)布层间不小于3.2n/mm,覆盖(Cover)胶与布层间不小于2.1n/mm

Cover layer: the tensile strength shall not be less than 15MPa, the elongation length shall not be less than 350%, the abrasion amount shall not be less than 200mm 3, the average value of longitudinal samples of the strength between layers shall not be less than 3.2n/mm, and the coverage adhesive shall not be less than 2.1n/mm

全厚度纵向扯断伸长率不小于10%,全厚度纵向参考力伸长率不大于1.5%

The longitudinal elongation at break of full thickness shall not be less than 10%, and the elongation at longitudinal reference force of full thickness shall not be more than 1.5%

输送带跑偏的原因

The cause of the belt deviation

在使用过程中,如果出现跑偏,则要作以下巡查以确定原因,进行进行调整。大倾角挡边输送带用于输送易散落的粉状、粒状、小块状、糊状及液态状物料。其特点:适用于倾角0°-90°散装物料的输送;具有使用范围广、占地面积小、无转运点、减少土建投资、维护费用低、维修容易输送量大连续化、率、大倾角运输,操作安全,使用简便,,运费低廉,并能缩短运输距离,降低工程造价,节省人力物力等特点。输送带跑偏时常巡查的部位和处理方法有:

In the use process, if there is deviation, the following inspection shall be conducted to determine the cause and make adjustment. The large angle edge retaining conveyor belt is used to transport powder, granular, small, paste and liquid materials which are easy to be scattered. Its characteristics: it is suitable for the transportation of bulk materials with an angle of 0 ° - 90 °; it has the characteristics of wide range of use, small floor area, no transfer point, reduced civil engineering investment, low maintenance cost, easy to maintain and transport Dalian, high efficiency, large angle transportation, safe operation, easy to use, low freight, and can shorten the transportation distance, reduce project cost, save manpower and material resources, etc. The frequently inspected parts and treatment methods for belt deviation are as follows:

(1)巡查托辊(gǔn)横向线与带式输送机纵向线的不重合度。大倾角挡边输送带用于输送易散落的粉状、粒状、小块状、糊状及液态状物料。其特点:适用于倾角0°-90°散装物料的输送;具有使用范围广、占地面积小、无转运点、减少土建投资、维护费用低、维修容易输送量大连续化、率、大倾角运输,操作安全,使用简便,,运费低廉,并能缩短运输距离,降低工程造价,节省人力物力等特点。如果不重合度值超过3mm,则应利用托辊(gǔn)组两侧的长形安装孔对其进行调整。具体方法是输送带偏向哪一侧,托辊组的哪一侧向输送带前进的方向前移,或另外一侧后移。

(1) Inspect the misalignment between the horizontal center line of idler (g ǔ n) and the vertical center line of belt conveyor. The large angle edge retaining conveyor belt is used to transport powder, granular, small, paste and liquid materials which are easy to be scattered. Its characteristics: it is suitable for the transportation of bulk materials with an angle of 0 ° - 90 °; it has the characteristics of wide range of use, small floor area, no transfer point, reduced civil engineering investment, low maintenance cost, easy to maintain and transport Dalian, high efficiency, large angle transportation, safe operation, easy to use, low freight, and can shorten the transportation distance, reduce project cost, save manpower and material resources, etc. If the non coincidence value exceeds 3mm, it shall be adjusted by using the long mounting holes on both sides of the idler (g ǔ n) group. The specific method is that which side of the conveyor belt is biased, which side of the idler group moves forward to the direction of the conveyor belt, or the other side moves backward.

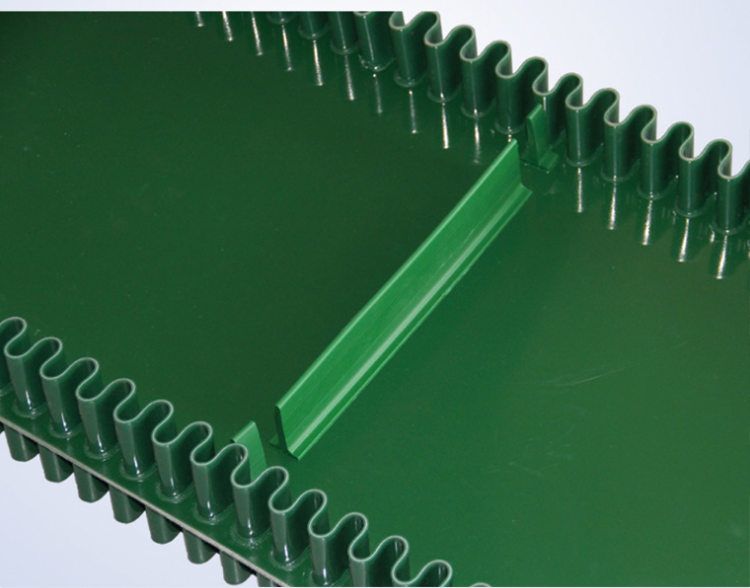

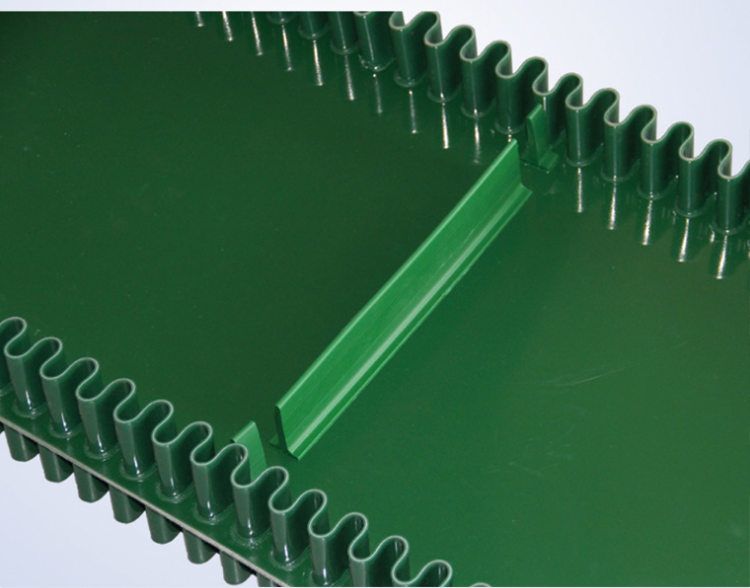

(2)巡查头、尾机架安装轴承(bearing)座的两个平面的偏差值。大倾角挡边输送带又叫裙边隔板输送带,是由基带、挡边、横隔板3部分组成。挡边起防止物料测滑撒落的作用。解决了普通带和花纹带所不能达到的输送角度;还可根据使用环境,设计成完整、独立的输送系统,避免了间断输送和复杂输送的提升系统。可沿水平、倾斜、垂直和变角方向输送各种散装物料,从煤、矿石、沙子到化肥和粮食等。若两平面的偏差大于1mm,则应对两平面调整在同一平面内。头部滚筒的调整方法是:若输送带向滚筒的右侧跑偏,则滚筒右侧的轴承(bearing)座应当向前移动或左侧轴承座后移;若输送带向滚筒的左侧跑偏,则滚筒左侧的轴承座应当向前移动或右侧轴承座后移。尾部滚筒的调整方法与头部滚筒刚好相反。

(2) Inspect the deviation value of two planes of the mounting bearing seat of the head and tail frame. The high angle edge blocking conveyor belt, also known as skirt partition conveyor belt, is composed of baseband, edge blocking and diaphragm. The edge guard is used to prevent the material from sliding and scattering. It solves the conveying angle that ordinary belt and pattern belt can't reach; it can also be designed as a complete and independent conveying system according to the use environment, avoiding the lifting system of discontinuous conveying and complex conveying. It can transport all kinds of bulk materials, from coal, ore, sand to fertilizer and grain, along the horizontal, inclined, vertical and variable angle directions. If the deviation between the two planes is greater than 1mm, the two planes shall be adjusted in the same plane. The adjustment method of the head drum is: if the conveyor belt deviates to the right side of the drum, the bearing seat on the right side of the drum shall move forward or the bearing seat on the left side shall move backward; if the conveyor belt deviates to the left side of the drum, the bearing seat on the left side of the drum shall move forward or the bearing seat on the right side shall move backward. The adjustment method of the tail roller is just opposite to that of the head roller.

(3)巡查物料在输送带上的位置(position)。物料在输送带横断面上不居中,将导致输送带跑偏。

(3) Inspect the position of the material on the conveyor belt. If the material is not centered on the cross-section of the conveyor belt, the conveyor belt will deviate.