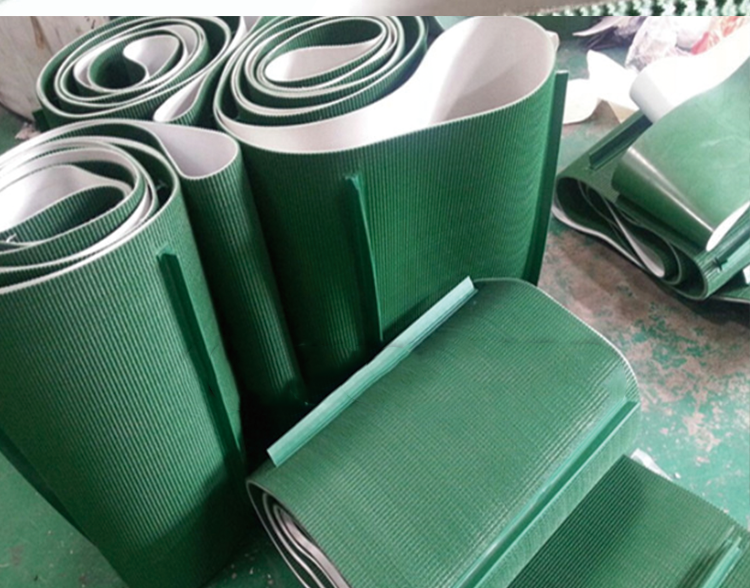

橡胶输送带主要是因为它的材料是由橡胶制成的,所以根据橡胶的不同类型和功能,可以分为耐磨性、耐热性、耐寒性、耐碱性等不同类型的输送带。不同的行业在使用橡胶输送带的过程中会遇到不同的问题,但大多数都会遇到打褶的现象,如何应对这种情况?下面对输送带厂家有详细的了解。

Rubber conveyor belt is mainly made of rubber. According to different types and functions of rubber, it can be divided into different types of conveyor belt, such as wear resistance, heat resistance, cold resistance and alkali resistance. Different industries will encounter different problems in the process of using rubber conveyor belt, but most of them will encounter the phenomenon of pleating. How to deal with this situation? The following has a detailed understanding of conveyor belt manufacturers.

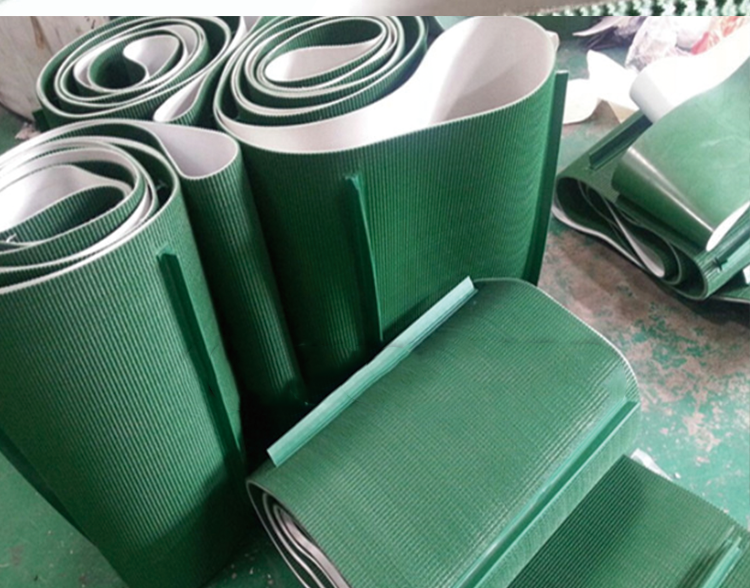

橡胶输送带的带体有时会出现弯曲和拆卸现象,严重影响输送带的性能,不利于安全生产。原因如下:钢坯两侧的厚度不同,较厚的一侧容易拉伸,且长度不一致,会造成弯曲。带芯的带钢不合理,胶带两边的匹配不一致,导致其张力与相同,弹性也不同,这必然会使输送带弯曲打折。张力器夹持角度控制不好。当它与主机不直时,很容易拉动斜带毛坯,形成弯曲折弯的形状。

Sometimes the rubber conveyor belt body will be bent and disassembled, which seriously affects the performance of the conveyor belt and is not conducive to safety production. The reasons are as follows: the thickness of the two sides of the billet is different, the thicker side is easy to stretch, and the length is not the same, which will cause bending. The belt with core is unreasonable, and the matching of both sides of the belt is not consistent, resulting in the same tension and different elasticity, which will inevitably make the conveyor belt bend and discount. The holding angle of the tensioner is not well controlled. When it is not straight with the host machine, it is easy to pull the inclined belt blank to form a bending shape.

橡胶传送带向前运行支持和牵引FQ,支持和旋转力Fz和横向力FC牵引分解,辊的轴向移动的横向分量,辊支撑固定辊不是轴向运动,它将不可避免地产生一个反作用力财政年度传送带,它使传送带移动到另一边,导致偏差。很明显,托辊组安装过程中的挠度力是造成橡胶输送带偏差的原因,调节方法也很明确。

The rubber conveyor belt moves forward to support and pull FQ, support and rotation force FZ and transverse force FC to pull and decompose, the transverse component of the axial movement of the roller, the fixed roller of the roller support is not axial movement, it will inevitably produce a reaction force fiscal year conveyor belt, it makes the conveyor belt move to the other side, leading to deviation. It is obvious that the deflection force during the installation of the idler group is the cause of the rubber conveyor belt deviation, and the adjustment method is also very clear.

以上是橡胶输送带在使用中出现的打褶现象的原因及解决方法,希望对您有所帮助。有关橡胶输送带的更多信息,请关注我们的网站以了解更多。

The above is the reason and solution of the pleating phenomenon in the use of rubber conveyor belt. I hope it can help you. For more information about rubber conveyor belts, please follow our website to learn more.