随着采矿材料的使用不断增加,相应的采矿规模也在不断增加。 在生产过程中,有必要在安全的前提下保证工作的正常进行。 因此,对于带式输送机的稳定运行的要求也非常重要。 将使用带式输送机的更平稳操作的更详细说明:

With the increasing use of mining materials, the corresponding mining scale is also increasing. In the production process, it is necessary to ensure the normal operation under the premise of safety. Therefore, it is very important for the stable operation of belt conveyor. A more detailed description of the smoother operation of the belt conveyor will be used:

带式输送机是采矿必不可少的:它们具有容量大,传输距离长,连续运输等优点,并可用于自动遥控。 因此,输送机设备被广泛使用,但是具有快速的自动化技术。 产量的增加和增加,对操作需求和效率的要求更高,生产过程中工作强度更高的大角度长距离带式输送机,目前的大倾角可以达到50度,但同时还有大倾角 首先,必须特别注意设备的操作稳定性。 除了配置高效的制动设备外,还需要科学合理的布局以使皮带输送机设备更稳定地运行。

Belt conveyors are essential for Mining: they have the advantages of large capacity, long transmission distance, continuous transportation and can be used for automatic remote control. Therefore, conveyor equipment is widely used, but it has rapid automation technology. With the increase of production, the operation demand and efficiency are higher, and the working intensity is higher in the production process. At present, the maximum inclination angle of the large angle long-distance belt conveyor can reach 50 degrees, but at the same time, there is a large inclination angle. First of all, special attention must be paid to the operation stability of the equipment. In addition to efficient braking equipment, scientific and reasonable layout is also needed to make the belt conveyor equipment run more stably.

如果皮带输送机运输大量矿物材料,则该材料将粘附在裙边皮带上,并且滑动力将导致整个机器向后下落。 这将导致异常事故。 为了避免此类问题,有必要配置可靠的保护。 换向装置保证了大角度皮带输送机的稳定运行。 选择的前提是在大工作能力下测量输送机的滑动力矩,例如考虑到紧凑的结构和易于安装的情况,并且机器空间过大。 从尾部装载点到行驶前十米的距离,尾架和尾部中间框架的安装角度减小到小于30度,从而使整机的安装倾斜角小于 要加载的原始物料的动态倾倒角度。 物料稳定在橡胶带上后,进入大倾角的工作状态;

If the belt conveyor transports a large amount of mineral material, the material will adhere to the skirt belt and the sliding force will cause the whole machine to fall backward. This will lead to abnormal accidents. In order to avoid such problems, it is necessary to configure reliable protection. The reversing device ensures the stable operation of the large angle belt conveyor. The premise of selection is to measure the sliding moment of the conveyor under the maximum working capacity, for example, considering the compact structure and easy installation, and the machine space is too large. From the tail loading point to the ten meters before driving, the installation angle of the tail frame and the tail middle frame is reduced to less than 30 degrees, so that the installation inclination angle of the whole machine is less than the dynamic dumping angle of the original material to be loaded. After the material is stable on the rubber belt, it enters into the working state of large inclination angle.

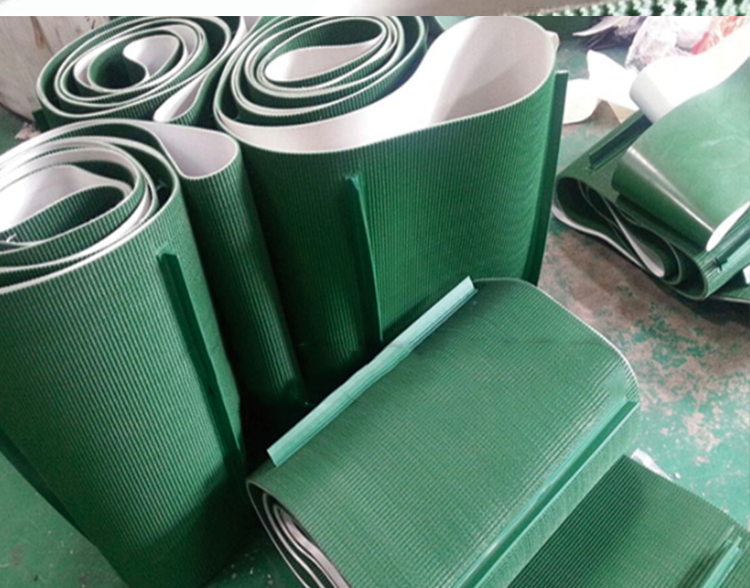

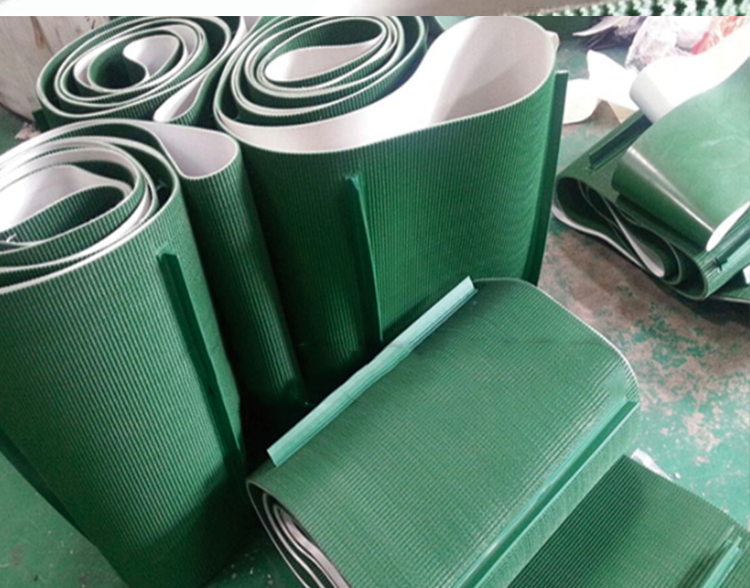

为避免输送带在皮带输送机中滑动的问题,可以选择高强度阻燃钢丝绳芯抗撕裂输送带,以增加皮带表面与皮带主体之间的摩擦阻力。 深沟形状。 在皮带轮上,胶印滚筒上的凹槽角度为六十度,以增加物料与钢丝绳输送带之间的侧向压力,从而防止整个机器在使用中使用 输送带。 承载能力需要与合适的加载机制相匹配,然后根据现场条件选择合适的角度。 溜槽设计为铲形,下料方向从垂直方向变为水平方向,从而确保了顺畅的输送并减少了对皮带的影响。 ;

In order to avoid the problem of belt sliding in the belt conveyor, high-strength flame-retardant steel cord tear resistant conveyor belt can be selected to increase the friction resistance between the belt surface and the belt main body. Deep groove shape. On the pulley, the groove angle on the offset roller is 60 degrees to increase the lateral pressure between the material and the wire rope conveyor belt, so as to prevent the whole machine from using the conveyor belt in use. The bearing capacity needs to match with the appropriate loading mechanism, and then select the appropriate angle according to the site conditions. The chute is designed as spade shape, and the blanking direction changes from vertical direction to horizontal direction, so as to ensure smooth transportation and reduce the impact on the belt. ;

另外,选择合适的变频软启动方式,并在上部皮带上设置密闭保护装置,以防止由于过大的倾斜角度而引起滚动状况,密闭刮板置于中间。 下部皮带的角度,以防止材料向机器滚动。 这些尾部对于输送机的平稳运行非常重要。 合理的保护尾巴可以防止由于碎屑和石头引起的皮带偏移和皮带断裂等异常情况。 我们可以完全闭合尾巴;

In addition, select a suitable frequency conversion soft start mode, and set up a closed protection device on the upper belt to prevent rolling due to too large tilt angle. The closed scraper is placed in the middle. The angle of the lower belt to prevent material from rolling towards the machine. These tails are very important for the smooth operation of the conveyor. Reasonable tail protection can prevent belt deviation and belt fracture caused by debris and stones. We can close the tail completely;

后,增加存储容量以减少带式输送机的频繁运行,避免超载运行,严格控制物料的水分,消除其他生产和运输环节中的水混合,胶带图案的磨损和修复,技术分析等 现场观察,大浸入带当机器以恒定速度运行时,由于材料和防滑橡胶输送带的摩擦阻力,滑动速度的增加会增加工业橡胶带花纹的磨损。 如果不及时修理,则磁带将无法传送材料。 因此,有必要使用的橡胶冷粘接方法进行及时修补;

Finally, increase the storage capacity to reduce the frequent operation of the belt conveyor, avoid overload operation, strictly control the moisture content of the material, eliminate the water mixing in other production and transportation links, wear and repair of the belt pattern, technical analysis and other field observation. When the large immersion belt is running at a constant speed, due to the friction resistance of the material and the antiskid rubber conveyor belt, the sliding speed The increase of degree will increase the abrasion of industrial rubber belt pattern. If not repaired in time, the tape will not be able to transfer the material. Therefore, it is necessary to use a professional rubber cold bonding method for timely repair;