我们都知道运输机上的输送带是环形结构,但是从厂家销售的输送带通常不是环形结构。为了正常使用输送带,我们需要对输送带进行粘接。因此,钢丝绳输送带接头的质量对输送带的后续使用非常重要,良好的钢丝绳输送带接头可以延长输送带的使用寿命,同时也保证了输送带在运行过程中的平稳运行。现在要介绍如何安装以下连接器技巧。

We all know that the conveyor belt on the conveyor is a ring structure, but the conveyor belt sold from the manufacturer is usually not a ring structure. In order to use the conveyor belt normally, we need to bond the conveyor belt. Therefore, the quality of wire rope conveyor belt joint is very important for the subsequent use of the conveyor belt. A good wire rope conveyor belt joint can extend the service life of the conveyor belt and ensure the smooth operation of the conveyor belt in the operation process. Now I'll show you how to install the following connector tips.

1、安装接头的方法有很多,常用的方法有机械接头、冷粘接头和热硫化接头。机械接头一般为带式搭扣接头,安装方便快捷。然而,缺点是它们的效率低于其他关节,很容易被损坏。尽管有一些缺点,机械关节仍然被许多人使用。一般情况下,8级皮带下的输送带都要用这种接头连接。

1. There are many ways to install the joint. The common methods are mechanical joint, cold bonded joint and hot vulcanized joint. The mechanical joint is generally a belt type buckle joint, which is easy to install. However, the disadvantage is that their efficiency is lower than other joints, and they are easy to be damaged. Despite some shortcomings, mechanical joints are still used by many people. In general, the conveyor belt under Grade 8 Belt should be connected with this joint.

2,有一种冷胶接接头,其原则是和冷粘混合成键,该方法与上面提到的机械耦合效率会更高,但是不是很经济实惠,困难的,它需要的技术条件较高,胶粘剂的要求也很高,使用实际情况不是很稳定。与冷粘接相比,热粘接是目前实际应用中更理想的方法。它具有效率高、稳定性好、使用寿命长、操作方便等优点。其缺点是操作过程复杂、成本高、运行时间长。

2. There is a cold bonding joint, the principle of which is to mix with cold bonding to form a bond. The mechanical coupling efficiency of this method and the above mentioned one will be higher, but it is not very economical and difficult. It requires high technical conditions, high requirements for adhesives, and the actual situation of use is not very stable. Compared with cold bonding, hot bonding is the most ideal method in practical application. It has the advantages of high efficiency, good stability, long service life and convenient operation. Its disadvantages are complex operation process, high cost and long running time.

3,胶钢丝绳输送带不一定只有一个方法,一个完整的环形输送带可能不只有一个联合,根据需要采取不同的联合方法债券,通常使用冷胶关节和热硫化接头在加强结构的联合方法。上述方法为层状输送带接头的安装方法。

3. There is not necessarily only one method for rubber wire rope conveyor belt, but also not only one joint for a complete circular conveyor belt. Different joint methods are adopted according to the needs of bonds. Usually, the joint method of cold rubber joint and hot vulcanization joint is used to strengthen the structure. The above method is the installation method of layered conveyor belt joint.

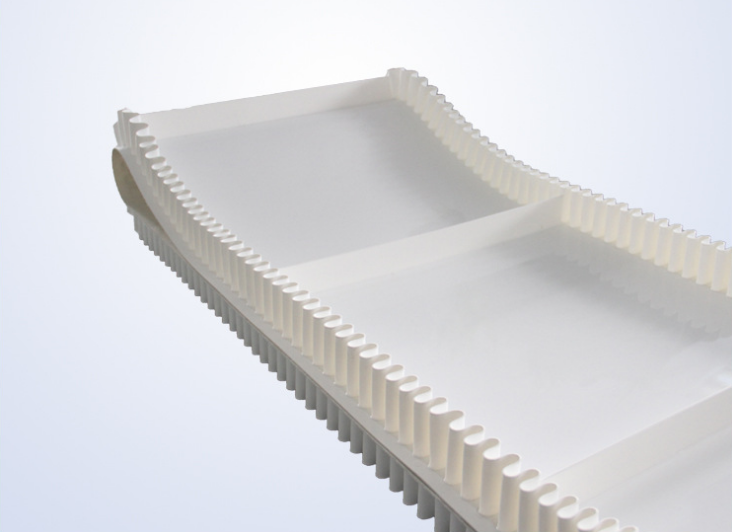

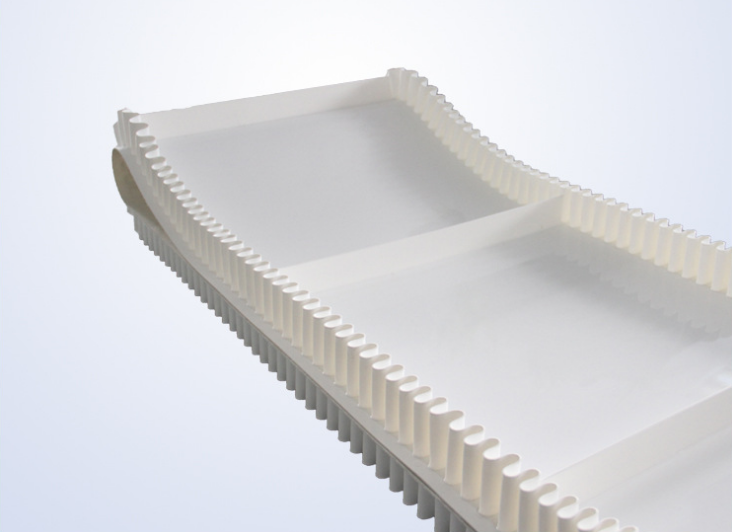

4. 不同的输送机安装接头的方法不同,更难安装接头的输送带是PVC和PVG全芯阻燃输送带。由于输送带的特殊结构,安装比较困难。8级以下的安装主要采用机械接头,8级以上的输送带仍采用热硫化接头,以保证输送带的使用效果。需要注意的是,这种关节的结构是指形的,以便更好的连接关节。

4. Different conveyor has different installation methods of joints. The conveyor belt with the most difficult joints is PVC and PVG full core flame retardant conveyor belt. Due to the special structure of conveyor belt, it is difficult to install. The mechanical joint is mainly used for the installation below grade 8, and the thermal vulcanization joint is still used for the conveyor belt above grade 8 to ensure the use effect of the conveyor belt. It should be noted that the structure of this joint is finger shaped in order to better connect the joints.

以上就是对钢丝绳输送带接头的简单介绍,为了保证输送带的正常运转,接头是非常重要的环节,在连接接头时一定不能掉以轻心。

The above is a brief introduction to the joint of the steel wire rope conveyor belt. In order to ensure the normal operation of the conveyor belt, the joint is a very important link. When connecting the joint, it must not be taken lightly.