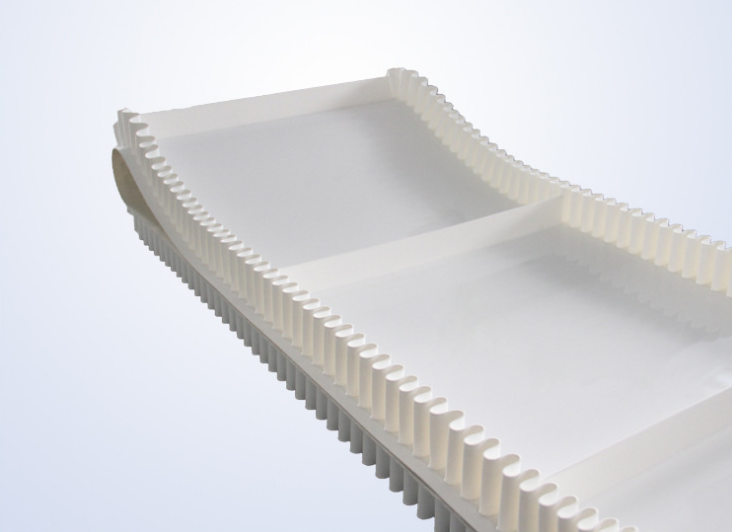

,我们必须确保输送机本身没有问题。高温输送带只是一个轮毂,它的运行依赖于输送装置。设备的质量是决定皮带能否正常运行的一个因素。

First of all, we have to make sure that the conveyor itself is OK. High temperature conveyor belt is only a hub, its operation depends on the conveyor. The quality of the equipment is a factor that determines whether the belt can operate normally.

其次,输送带是否与输送带布置相匹配,是否适合运输此类货物,是决定输送带正常运行的因素。传送带的状态是否良好,问题是否得到处理,货物放置在传送带上是否合理,将直接影响传送带的运行。

Secondly, whether the conveyor belt matches the layout of the conveyor belt and is suitable for transporting such goods is the factor that determines the normal operation of the conveyor belt. Whether the conveyor belt is in good condition, whether the problems are handled and whether the goods are placed on the conveyor belt reasonably will directly affect the operation of the conveyor belt.

此外,操作人员应具有操作输送机设备和维修输送带的知识,发现问题,及时维修和及时处置,危害将被扼杀在摇篮里。

In addition, the operator shall have the professional knowledge to operate the conveyor equipment and repair the conveyor belt, find problems, repair and dispose in time, and the hazards will be strangled in the cradle.

胶带的正常运行会影响企业的生产效率,应引起重视。

The normal operation of the tape will affect the production efficiency of the enterprise, which should be paid attention to.

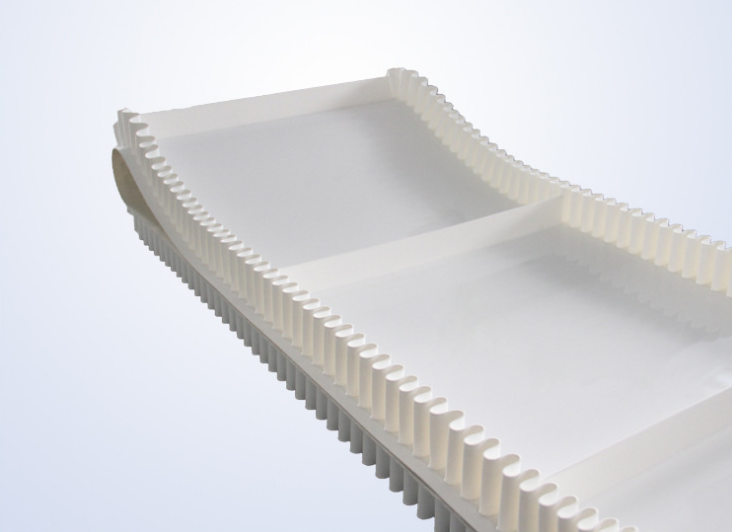

耐高温输送带在使用过程中,剥离主要是由于覆盖层与芯体之间的粘结力和强度较低,主要是由以下原因造成的:

During the use of high temperature resistant conveyor belt, the peeling is mainly due to the low adhesion and strength between the covering layer and the core, which is mainly caused by the following reasons:

1芯糊塑化后换辊后的脏东西。

1. Dirt after roll change after core paste plasticization.

2芯糊塑料与面糊不能很好的结合。

2-core paste plastic and paste can not be well combined.

增塑剂在三芯膏体中的沉淀降低了芯体表面的粘度和强度。

The precipitation of plasticizer in the three core paste reduces the viscosity and strength of the core surface.

易碎的材料也限制了速度。当耐高温输送带通过辊筒输送物料时,应采用粉料以足够低的带速输送。较低的带速会使易碎物料在装卸点不会发生跳跃断裂。边缘锋利的重物应以中速运输。因为边缘会过度磨损输送带的表面,特别是当加载速度明显低于输送带的速度时。提高输送带速度可以降低带宽和输送带张力。然而,在带来上述好处的同时,我们还需要平衡皮带可能存在的磨损、材料跳动、气流阻力、承重辊本体冲击、皮带各部分寿命降低等弊端。

Brittle materials also limit speed. When the high temperature resistant conveyor belt transports the material through the roller, the powder material shall be transported at a sufficiently low belt speed. A lower belt speed will prevent brittle materials from jumping and breaking at the loading point. Sharp edged loads should be transported at medium speed. Because the edge will wear the surface of the conveyor belt excessively, especially when the loading speed is significantly lower than the speed of the conveyor belt. Increasing belt speed can reduce belt width and belt tension. However, in addition to the above benefits, we need to balance the possible disadvantages of the belt, such as wear, material runout, air flow resistance, impact of the bearing roller body, reduction of the life of each part of the belt, etc.