冷运输与很多事情不清楚门外汉,冷输送带接头的过程,ermeng有时根据粘结法来完成所有的过程中,也会发现联合不是困,剥离联合后,发现粘合剂层不粘,表面的胶水,闪闪发光,这是“使过干”的现象。这是在刷胶干燥或发酵过程,以确保完全挥发性溶剂,确保完成硫化橡胶,太多的干燥或烘烤时间更长,使胶粘剂已经完全治愈或更快的完全固化,使两个子的关节表面分子间作用力和化学反应很小,导致接头粘不住。

Cold transportation and many things are not clear to laymen, cold conveyor belt joint process, Ermeng sometimes according to the bonding method to complete all the process, will also find that the joint is not trapped, peel joint, found that the adhesive layer is not sticky, the surface of the glue, glittering, this is "make too dry" phenomenon. This is in the process of brushing, drying or fermentation, to ensure the complete volatile solvent, to ensure the completion of vulcanized rubber, too much drying or baking time is longer, so that the adhesive has been completely cured or completely cured faster, so that the intermolecular force and chemical reaction between the two sub joint surfaces are very small, resulting in joint adhesion.

这个要求当我们在空气中购买或烘烤时,根据实际情况,如温度、天气、控制适当的时候,都以确保渗透溶剂蒸发的传送带,使橡胶和粘性,能保证次完全干燥,注意第二次,第三次感觉粘性胶胶水没有干水分。检查托辊的横向线是否与带式输送机的纵向线不重合。如果non-coincidence值超过3毫米时,应通过调整长安装孔两边的惰。具体方法是哪一方倾向于输送带,托辊组的哪一边传送带的方向前进,或者另一边移动。检查轴承座安装在头部和尾部框架上的两个平面的偏差值。如果两个平面的偏差大于1mm,则应将两个平面调整在同一平面上。

This requires that when we buy or bake in the air, according to the actual situation, such as temperature, weather, when the control is appropriate, we should ensure that the conveyor belt permeated with solvent evaporation can make the rubber and viscosity completely dry for the first time, and pay attention to the second time and the third time when we feel that the adhesive glue has no dry water. Check whether the transverse center line of the idler does not coincide with the longitudinal center line of the belt conveyor. If the non coincidance value is more than 3mm, adjust the idling on both sides of the long mounting hole. The specific method is which side is inclined to the conveyor belt, which side of the idler group is moving in the direction of the conveyor belt, or the other side is moving. Check the deviation value of two planes of the bearing seat installed on the head and tail frame. If the deviation of the two planes is greater than 1mm, the two planes shall be adjusted on the same plane.

头滚筒的调整方法如下:输送带向滚筒右侧偏移时,滚筒右侧的轴承座向前移动或左侧的轴承座向后移动;如果输送带偏离滚筒左侧,则滚筒左侧的轴承座向前移动,或右侧的轴承座向后移动。尾鼓的调节方法与头鼓的调节方法相反。检查输送带上物料的位置。如果物料没有集中在输送带的横截面上,就会导致输送带的偏移。输送带也不例外,它们的老化比率是88,老化后的拉伸性能退化很多,只有40%的水平。结果,性能大大降低。

The adjustment method of the head drum is as follows: when the conveyor belt is offset to the right side of the drum, the bearing pedestal on the right side of the drum moves forward or the bearing pedestal on the left side moves backward; if the conveyor belt is deviated from the left side of the drum, the bearing pedestal on the left side of the drum moves forward or the bearing pedestal on the right side moves backward. The adjustment method of tail drum is opposite to that of head drum. Check the position of the material on the conveyor belt. If the material is not concentrated on the cross section of the conveyor belt, the conveyor belt will be offset. Conveyor belts are no exception. Their maximum aging ratio is 88. After aging, the tensile properties degrade a lot, only 40%. As a result, the performance is greatly reduced.

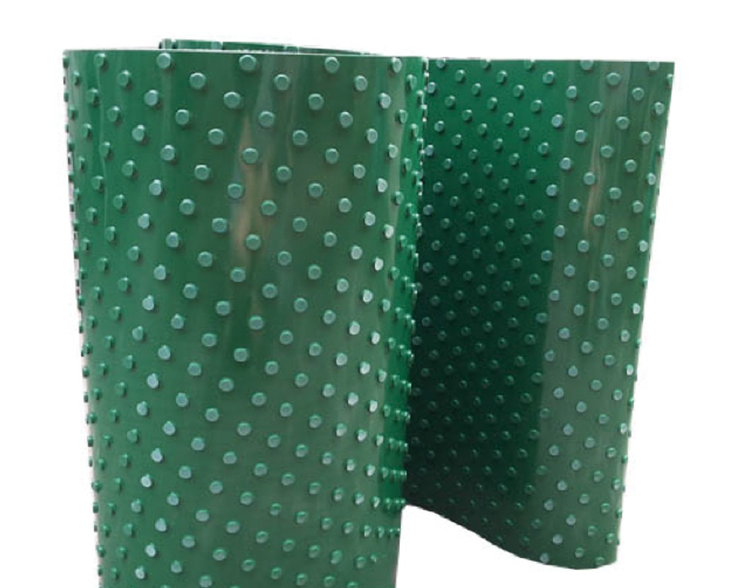

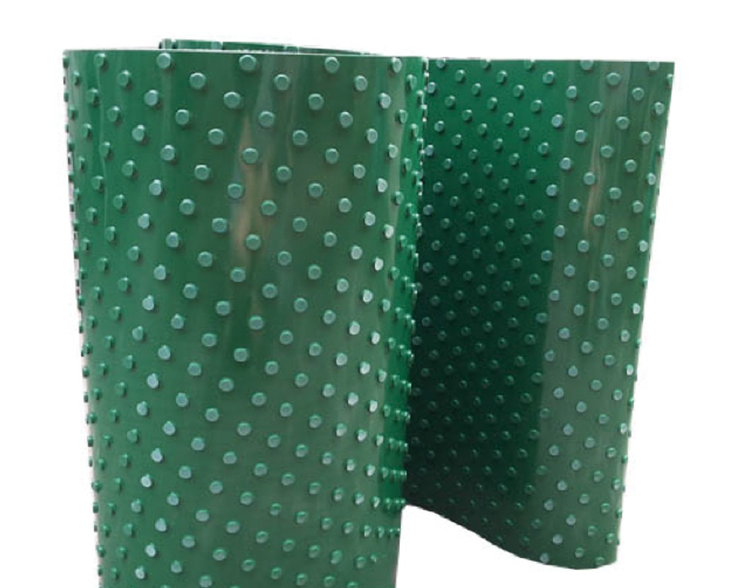

钢丝网耐高温输送带是由耐高温材料和钢丝制成的,钢丝表面会镀上金属,然后再覆盖一层耐高温橡胶,形成耐高温钢丝输送带。耐高温钢丝输送带的可靠性有了很大的提高,表面不会出现分层现象,与纯耐高温输送带相比更加稳定。胶带生产中有不同之处,不同的托辊生产厂家生产的胶带配方略有不同。这些产品可以由不同的输送带厂家销售混合吗?这样说不是太好,因为这样,和不同的交货生产工艺,简单地说,配方不一定是同一辊造成的。

The steel wire mesh high temperature resistant conveyor belt is made of high temperature resistant materials and steel wires. The steel wire surface will be plated with metal, and then covered with a layer of high temperature resistant rubber to form a high temperature resistant steel wire conveyor belt. The reliability of high temperature resistant steel wire conveyor belt has been greatly improved, the surface will not be stratified, and it is more stable than pure high temperature resistant conveyor belt. There are some differences in the production of belt, and the formula of belt produced by different idler manufacturers is slightly different. Can these products be sold and mixed by different belt manufacturers? That's not very good, because in this way, with different delivery and production processes, simply speaking, the formula is not necessarily caused by the same roller.