带式输送机是一种通用的输送机械。随着经济的发展,它已经服务于国民经济建设的各个领域。带式输送机可完成物料的水平、倾斜、垂直输送,也可实现单台或多台长距离输送。根据行业使用和工作条件,客户可以选择适合自己需要的带式输送机。带式输送机因其输送距离长、输送能力大、运输连续、操作简单、自动化程度高、管理集中等特点,已成为矿山运输设备的必备产品。今天,我们来谈谈带式输送机的结构。

Belt conveyor is a kind of general conveying machinery. With the development of economy, it has served all fields of national economic construction. The belt conveyor can complete the horizontal, inclined and vertical transportation of materials, and also can realize the long-distance transportation of single or multiple sets. According to the use and working conditions of the industry, customers can choose the belt conveyor suitable for their own needs. Belt conveyor has become a necessary product of mine transportation equipment because of its long transportation distance, large transportation capacity, continuous transportation, simple operation, high automation and centralized management. Today, let's talk about the structure of belt conveyor.

带式输送机主要由以下部件组成:

The belt conveyor is mainly composed of the following parts:

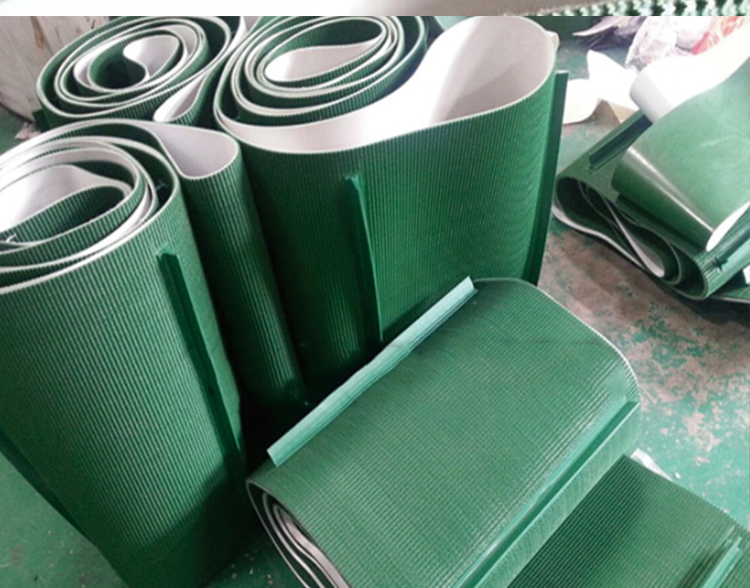

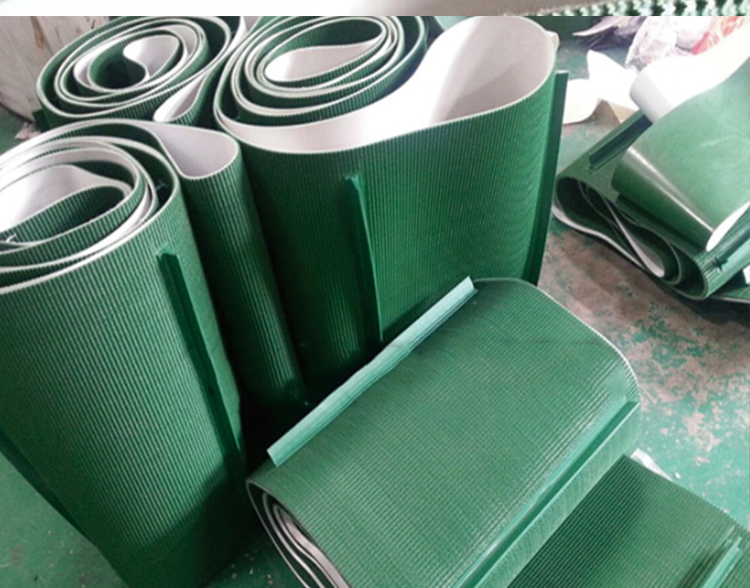

1. 输送带:输送带的牵引力和承载能力。可根据工作条件选择高温输送带和波纹罗纹输送带。

1. Conveyor belt: traction and bearing capacity of conveyor belt. High temperature conveyor belt and corrugated rib conveyor belt can be selected according to working conditions.

2. 驱动:它是输送机的动力部分。

2. Drive: it is the power part of the conveyor.

3.传动滚筒:传动滚筒是动力传动的主要部件,传动皮带由传动皮带与传动滚筒之间的摩擦来运转。

3. Drive drum: the drive drum is the main part of power transmission, and the drive belt is operated by the friction between the drive belt and the drive drum.

4. 改向滚筒:用来改变输送带的运行方向。改向辊用于输送带的下表面。

4. Direction changing roller: used to change the running direction of the conveyor belt. The deflection roller is used for the lower surface of the conveyor belt.

5. 压轮:用来改变输送带的运行方向。压辊用于输送带的上表面。

5. Pressing wheel: used to change the running direction of the conveyor belt. The pressing roller is used for the upper surface of the conveyor belt.

6. 托辊:托辊用于支撑输送带上的物料,使输送带平稳运行。

6. Idler: the idler is used to support the materials on the conveyor belt to make the conveyor belt run smoothly.

7. 托辊:托辊用于在凸圆弧框架上支撑输送带下支,支撑输送带两侧的空气侧。

7. Idler: the idler is used to support the lower support of the conveyor belt on the convex arc frame and the air side on both sides of the conveyor belt.

8. 垂直辊:垂直辊用于限制输送带的偏差,安装在上下过渡架上。每个过滤部分有四个机架,每边两个。

8. Vertical roll: the vertical roll is used to limit the deviation of the conveyor belt and installed on the upper and lower transition frames. Each filter section has four racks, two on each side.

9. 砂轮清洗装置:用于撞击输送带背面,将卡在输送带上的物料抖掉。

9. Grinding wheel cleaning device: used to impact the back of the conveyor belt and shake off the materials stuck on the conveyor belt.

10. 张紧装置:其作用是:(1)输送足够的张紧力,保证输送带与驱动辊之间无滑移。(2)限制输送带支架之间的下垂,使输送带正常运行。

10. Tensioning device: its function is: (1) to transport enough tensioning force to ensure that there is no slippage between the conveyor belt and the driving roller. (2) limit the sagging between the conveyor belt supports to make the conveyor belt operate normally.

机架、机头漏斗、头罩、导向槽、中间机架、中间机架支架等:输送机的支撑、除尘、导向装置。

Frame, head funnel, head cover, guide groove, middle frame, middle frame support, etc.: support, dust removal and guide device of conveyor.

以上是带式输送机的各个部件,每个部件将根据不同的工作条件进行调整。

The above are the various parts of the belt conveyor, each part will be adjusted according to different working conditions.