1、缓冲托辊

1. Buffer idler

为防止输送带受到过大的冲击力,在投料部位应设置缓冲托辊(胶轮或小型轮胎),托辊要转动自如。

In order to prevent the conveyor belt from being subjected to excessive impact force, buffer idlers (rubber tires or small tires) should be set at the feeding position, and the idlers should rotate freely.

2、 挤胶

2. Extrusion

为防止物料啮入挤咬损坏胶带,在托辊和返回辊之间设置1—2毫米厚的铁板隔板和刮板。

In order to prevent the material from biting into the belt, a 1-2 mm thick iron plate partition and scraper are set between the idler and return roller.

3、 滚筒上块状附着物防止措施

3. Prevention measures of block attachment on drum

与上盖胶接触的滚筒上,附着物容易堆积成块,这就改变滚筒半径,致使输送带上钢丝绳张力不平衡若输送带继续运行,则会导致部分钢丝绳断裂事故的发生。因此为防止附着物堆积成块,必须在带轮上安装好清扫装置,尤其是头部和尾部的清扫装置更要完备。

On the drum in contact with the upper cover rubber, the attachments are easy to accumulate into blocks, which will change the drum radius and cause the tension imbalance of the steel wire rope on the conveyor belt. If the conveyor belt continues to run, it will lead to some wire rope fracture accidents. Therefore, in order to prevent the attachment from accumulating into blocks, the cleaning device must be installed on the pulley, especially the head and tail cleaning device should be more complete.

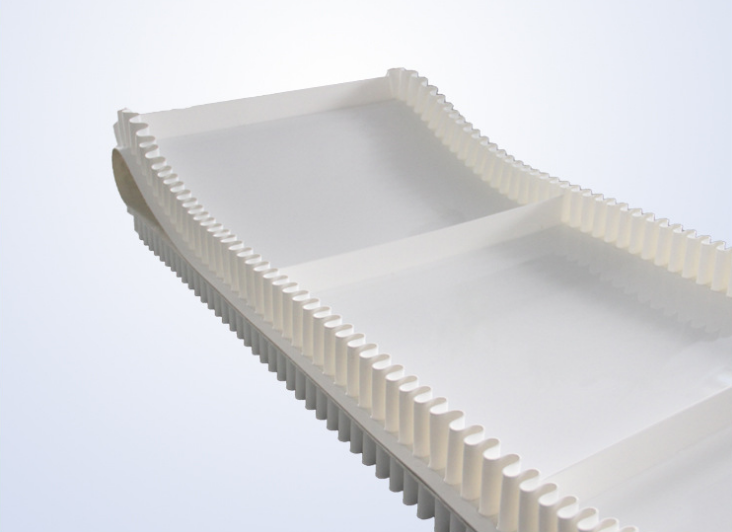

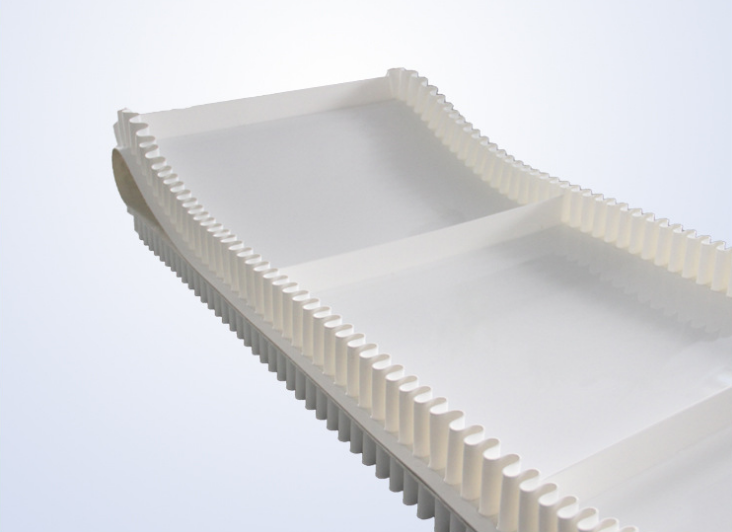

4、 头部和尾部成槽角

4. Groove angle of head and tail

钢丝绳芯输送带的成槽性能良好,成槽和头部和尾部辊筒之间的成槽角往往变化很急剧,此时输送带边部张力大,容易引起边胶异常磨损伤辊筒近处的托辊,也能引起钢丝绳断裂事故。为避免上述事故,把带轮近处的几组托辊的成槽角逐渐减少,以使成槽角变化缓慢。

The grooving performance of steel cord conveyor belt is good, and the groove angle between groove forming and head and tail roller often changes rapidly. At this time, the edge tension of conveyor belt is large, which is easy to cause abnormal wear of edge glue and damage to the roller near the roller, as well as wire rope fracture accident. In order to avoid the above accidents, the groove angle of several groups of idlers near the pulley is gradually reduced to make the groove angle change slowly.

5、输送带上升或下降弯曲点时,该处产生张力和压力的异常,容易使输送带边胶异常磨损,也能引起钢丝绳断裂。为避免这些事故,弯曲点处曲率半径尽可能要大,托辊的成槽角应小些,其配置也应密一些才好。

5. When the conveyor belt goes up or down the bending point, the tension and pressure will be abnormal, which will easily cause the abnormal wear of the belt edge glue, and also cause the wire rope to break. In order to avoid these accidents, the curvature radius at the bending point should be as large as possible, the groove angle of the idler should be smaller, and its configuration should be more dense.

6、钢丝绳芯输送带纵裂事故是难解决的问题,采用防撕裂型钢丝绳芯输送带,可以起到一定的效果,但仍需彻底搞好日常保养管理,才能防止纵裂事故,以下列出几项防纵裂措施:

6. However, the following measures can be taken to prevent longitudinal crack of conveyor belt

(1) 输送机装载段是输送带纵向撕裂多发区,特别是转载漏斗的溜槽出口处。因此,是预防输送带发生撕裂的重要环节。可在该处装设摆动梭式分离装置和溜槽斜格筛,以分离大块长件物料。

(1) The loading section of conveyor is the area where longitudinal tearing of conveyor belt occurs, especially at the outlet of chute of transfer hopper. Therefore, it is an important link to prevent the conveyor belt from tearing. Swing shuttle type separation device and chute inclined grid screen can be installed here to separate large and long materials.

(2) 在物料进入输送带之前的输送环节上加装电磁除铁器感应信号装置,作为防撕裂的一道关口。

(2) The induction signal device of electromagnetic iron remover is installed on the conveying link before the material enters the conveyor belt, as a pass to prevent tearing.

(3) 改善溜槽通过能力,增加溜槽通过高度,溜槽内隐患。

(3) Improve the capacity of the chute, increase the height of the chute, and eliminate the hidden danger in the chute.

(4) 在胶带卸料滚筒之前,漏斗之上部位设置防止胶带被铁件撕裂的防护板,防止铁器与胶带直接接触造成胶带划破。

(4) Before the belt unloading drum, a protective plate is set on the upper part of the funnel to prevent the belt from being torn by the iron parts, so as to prevent the iron ware from directly contacting with the belt and causing the belt to be scratched.