更近收到很多客户询问关于输送带滚筒和输送带之间的选择,然后输送带和滚筒之间的关系,本文做了一些简要的说明。

Recently, many customers have asked about the selection of conveyor belt roller and conveyor belt, and then the relationship between conveyor belt and roller, this paper makes some brief instructions.

,输送带越厚,相应滚筒的直径越大。这涉及到输送带能否正常运行以及输送带的使用寿命。

First, the thicker the belt, the larger the diameter of the corresponding drum. This involves whether the conveyor belt can operate normally and the service life of the conveyor belt.

接下来,我们将讨论输送带日常运行过程中的一些问题。针对这些问题,我们将分析输送带与滚筒之间的关系。

Next, we will discuss some problems in the daily operation of conveyor belt. To solve these problems, we will analyze the relationship between conveyor belt and roller.

1. 输送带偏差

1. Conveyor belt deviation

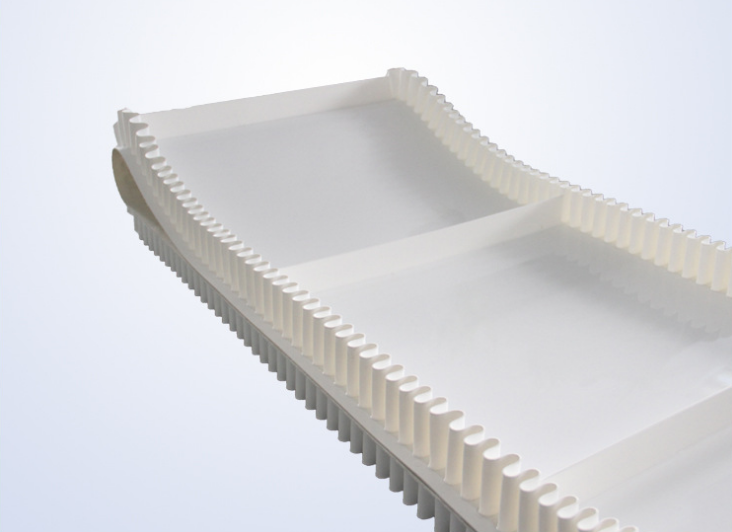

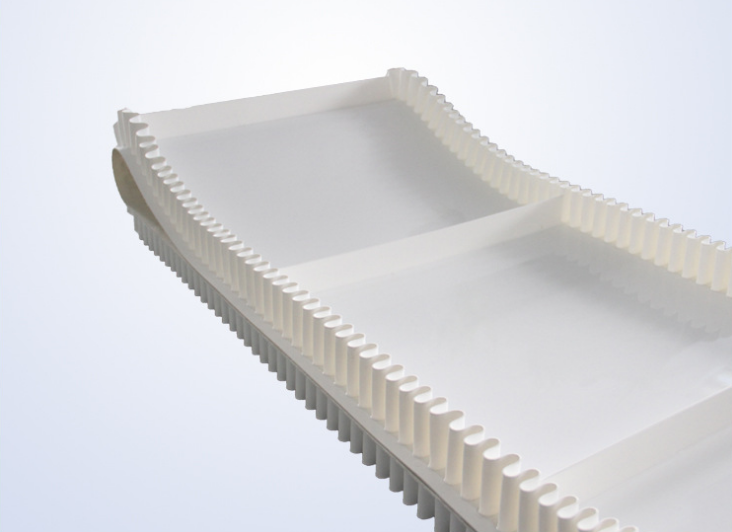

输送带在输送设备上跑偏是一种非常普遍的现象。从输送带与滚筒之间的配合来看,我们可以在调整输送带的前提下考虑使用圆弧滚筒。弧形滚筒可以改变输送带的整体受力,保证输送带在滚筒的运行

It is a very common phenomenon that the conveyor belt deviates on the conveying equipment. From the point of view of the cooperation between the conveyor belt and the roller, we can consider using the arc roller on the premise of adjusting the conveyor belt. The arc roller can change the overall stress of the conveyor belt and ensure the conveyor belt to run in the center of the roller

2. 传送带打滑了

2. Belt slipping

这里所说的输送带打滑可以分为两种情况:

The belt slip mentioned here can be divided into two situations:

在种情况下,新安装的输送带打滑或滚筒不转动。打滑的原因可能是滚筒的直径太小,造成打滑现象。在另一种情况下,传送带没有张紧。

In the first case, the newly installed conveyor belt slips or the drum does not rotate. The reason for the slipping may be that the diameter of the roller is too small, causing the slipping phenomenon. In another case, the belt is not tensioned.

第二种情况下,输送机使用现象,滚子和皮带滑了很长一段时间,所以这种情况的可能原因是,在辊运行很长一段时间,导致明亮辊表面的摩擦力变得较小,或摩擦力由辊磨损模式变得越来越小。

In the second case, the roller and belt slide for a long time due to the use of the conveyor, so the possible cause of this situation is that the friction force on the bright roller surface becomes smaller and smaller after a long period of roller operation, or the friction force becomes smaller and smaller from the roller wear mode.

3.输送带损坏

3. The conveyor belt is damaged

这第三点输送带断裂不是滚筒的主要问题。这种情况的出现主要是输送带的承载能力不够,输送带的选择过薄。经过这样的问题,我们主要考虑在滚筒直径允许的情况下使用较厚的输送带产品。

The third point is that the belt fracture is not the main problem of the drum. The main reason for this situation is that the carrying capacity of the conveyor belt is not enough and the selection of the conveyor belt is too thin. After such a problem, we mainly consider the use of thick conveyor belt products when the drum diameter allows.

以上就是对轻输送带和滚筒那些东西的总结,如果没有总结,或者有错的地方希望及时提出,大家一起商量,共同积累,共同进步。如果输送带有问题需要咨询,可以联系我们。

The above is the summary of the light conveyor belt and roller. If there is no summary, or there is something wrong, I hope to put it forward in time. We will discuss together, accumulate together and make progress together. If you have any questions about conveyor belt, please contact us.